Is it Safe to Laser Cut

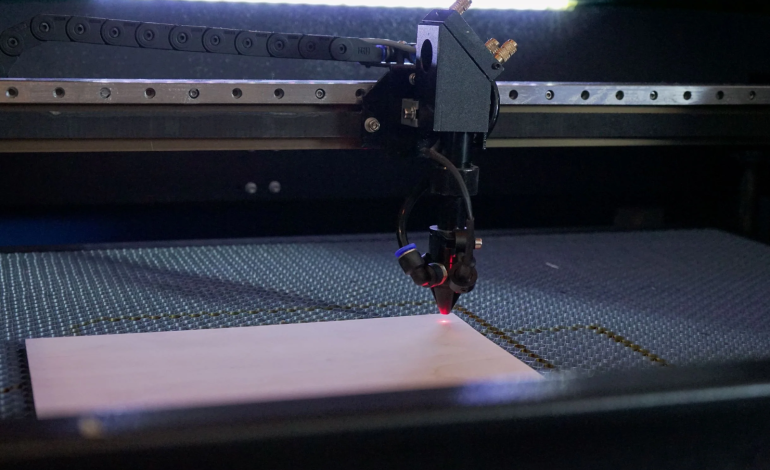

Laser cutting is a versatile process that employs a high-energy concentrated laser beam to cut into several sheet materials or plates to produce 2D components for industrial usage. Typical materials include wood, steel, and some polymers.

However, a laser cutter poses risks such as fires and the production of toxic and annoying combustion products. The laser cutter’s high-powered laser can cause eye and skin damage, so it must be contained within the cutter. This guide explains if it is safe to laser cut, the possible risks associated, and how to minimize them.

Is it Safe to Laser Cut?

Laser cutting can be a safe procedure if the necessary safeguards are taken. However, it does carry some hazards if not controlled properly. If suitable eye protection is not worn, the high-powered laser beam used for cutting can cause eye injury, including retinal damage and blindness. Furthermore, high temperatures produced during laser cutting can ignite flammable materials, resulting in flames and explosions.

To achieve safe laser cutting processes, specific safety protocols must be followed. This includes wearing protective eyewear, ensuring enough airflow, and using laser cutting machines with built-in safety measures. Operators should also be properly trained in the safe operation of laser cutting machines and adhere to specified safety rules.

When sufficient precautions are taken, laser cutting can be a safe and efficient industrial process. Many industries, such as manufacturing, textiles, woodworking, plastics, and jewelry & crafts, use laser cutting successfully and safely. By knowing the dangers and making efforts to mitigate them, manufacturers may reduce the risks connected with laser cutting while also providing a safe working environment for operators.

What Is Laser Cut?

Laser cutting is an industrial method that uses a powerful laser beam to cut or remove materials like metals, plastics, wood, and textiles. The laser beam is precisely regulated to melt, vaporize, or ablate (remove) material, resulting in a clean and exact cut.

Laser cutting is widely utilized in a variety of industries, including manufacturing, textiles, woodworking, plastics, jewelry, and crafts. In manufacturing, it is used to cut metal sheets, aluminum, and steel for applications such as construction, automotive, and aerospace. It is also used to cut fabric, leather, and other materials for fashion, upholstery, and industrial textile production.

Laser cutting offers great precision and accuracy, quick cutting speeds, minimal material waste, low heat input, and the ability to cut complicated forms and designs. However, as with any industrial operation, laser cutting has safety risks. These issues include the risk of eye injury from laser exposure, fire dangers, and the discharge of poisonous fumes during the cutting process.

To maintain safe laser-cutting procedures, it is critical to follow correct safety protocols, such as wearing protective eyewear, ensuring adequate ventilation, and using laser-cutting machines with built-in safety features. To reduce the dangers connected with laser cutting, personnel should receive sufficient training on how to use the devices safely and follow set safety requirements.

Safe Risk in Laser Cutting

Commercial laser cutters employ high-intensity lasers to make cuts. This process produces a lot of heat and needs a lot of power. Any configuration or alignment mistake can lead the laser to deviate from its intended path and strike something it shouldn’t. Let us look at some of the risks of laser cutting.

Shock Or Electrical Fire

Laser-cutting equipment uses a lot of electricity. A CO2 laser consumes 20 kilovolts of electricity, which is a significant amount of power. Such high voltages can easily shock you or start a fire if you configure it incorrectly or handle the unit carelessly. Diode lasers are significantly safer in this situation since they consume far less power.

Poor mains grounding and handling, as well as the use of low-quality connectors, wires, and other components, can cause electrical hazards. Electricity arcing out onto the laser cutter’s metal frame is a very regular problem. This video demonstrates how hazardous a defective laser cutter may be.

Burns

Another potential concern posed by laser cutters is the risk of starting a fire and being burned. When laser cutters cut material, they burn away a certain percentage of it. We are discussing steel, aluminum, and other metals, so you can imagine how hot the laser must be to achieve this.

However, most people mistake the threat posed by laser cutters. Metal laser cutting machines are generally safe.

The issues only arise when you leave a laser cutter alone. The machine’s modular components may become stuck, or you may misconfigure the cutting route, resulting in the machine lighting fire to the material you’re attempting to cut. Such situations are simple to resolve if you pay attention, but they can easily spiral out of control if left untreated.

Toxic Fumes

Laser cutters emit particles and fumes because they must burn some material away to cut objects. In some circumstances, cutting a substance produces very unpleasant-smelling fumes, while in others, the vapors are fatal.

For example, burning anything containing acrylic has an utterly disgusting odor that takes hours to remove, even with a powerful extraction machine. Chrome-tanned leather is highly poisonous when burned. When chlorine-containing materials react with airborne moisture, they produce hydrochloric acid. Fake leather is also a threat because it is constructed from PVC, which produces chlorine. The same applies to fiberglass, carbon fiber, and other thermoset materials.

Eye Damage

Radiation is the number one hazard when operating a laser cutter. The laser beams employed in laser cutters are infrared. They are invisible to the naked eye. These are extremely powerful and can blind you in a matter of seconds if they strike your eyes directly. Diode lasers are, admittedly, more harmful to the eyes than CO2 lasers because of how they interact with them.

But, let’s be honest: no one is going to put their eye in direct line with a laser cutter’s laser beam. People require protection from the continual radiation it generates. Typically, such light falls between 810 and 1060 nm in the near-infrared range.

The only way to make the laser more flexible and controllable is to move it through multiple mirror alignments. If you set things up correctly, the light will bounce in unexpected directions, which is different from what you want. That is why homemade laser-cutting machines are extremely dangerous.

How to Avoid Safe Risks in Laser Cutting

The risks of laser cutting may appear overwhelming, but there are simple strategies to reduce them. That is one of the reasons laser cutting has grown so popular. Here’s a list of recommendations for making laser cutting safer:

Mislabeling and Correct Settings

Before you laser-cut something, be sure you understand exactly what material it is comprised of. Some consumer-grade products have poor labeling, and misleading labels are common on items such as cellophane and clear acrylic. Check before putting anything under the laser to avoid any problems.

You must also select the appropriate setting for cutting. Do not layer your drawing in the—dxf file. Multiple layers on the same cutting line can provide a fire risk.

Extraction Unit

Extraction equipment provides the solution to your toxic fume problem. Most industrial laser cutters contain extraction and purifying units around the same size as the laser machine. These are simply air purification chambers. To deal with the fumes, you’ll need plenty of airflow. Low-end laser cutters do not come with such features, so you’ll have to make your own using a vent fan.

Enclosure

Simply putting a box around your laser cutter will fix 90% of your laser exposure issues. Industrial laser cutters have a separate housing, whereas low-end consumer devices do not.

Cheap laser cutters only have CNC and gantry and no other functionality. However, employing a laser cutter in an open environment is extremely dangerous because it may quickly fill your home with harmful fumes. You can make the enclosures yourself or have them manufactured at a nearby woodworking shop.

Maintenance and Caution

To avoid electrical risks, always inspect your laser cutter’s components, connectors, and other hardware before turning it on. The majority of typical electrical risks are caused by hardware failure and can be prevented by checking ahead of time.

Laser Goggles

One of the first pieces of safety equipment we propose is a pair of laser protective eyewear. These goggles can protect your eyes from laser radiation and direct exposure. When buying safety goggles, make sure they are OD-certified. If you have a diode laser cutter, you must get a pair of goggles that match your laser’s frequency range, or it will not function.

Conclusion

Laser cutting is an advanced procedure that requires careful consideration of safety protocols to reduce dangers. While it can present some risks, such as eye injury and fire threats, sufficient procedures and training can ensure a safe working environment. Manufacturers can reap the benefits of laser cutting by knowing the dangers and taking precautions to mitigate them, such as high precision and accuracy, fast cutting rates, and low material waste. Finally, if you are asking for “laser cutting near me,” look for the one with safe laser-cutting methods that are essential for protecting operators, equipment, and the entire manufacturing process.